Lihlahisoa

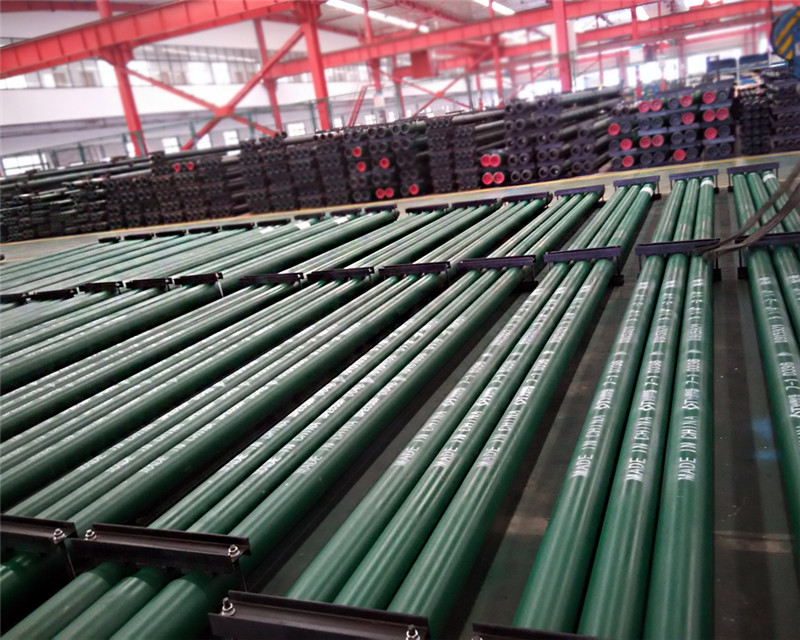

API 7-1 4145&Non-mag Drill Collar

Tlhaloso ea Sehlahisoa

Molala o tloaelehileng oa ho phunya ke karolo e chitja ea sefapano, setsi se na le lesoba la metsi, botenya ba lebota bo boholo, molomo o monyenyane, boima ba bolelele ba yuniti bo boholo ho feta boholo ba phala ea ho phunya hoo e batlang e le makhetlo a 4- 5. drill collar is thread processing directly on the pipe body , empa tse ling tsa tsona li boetse li sebelisa lenonyeletso le nketsoeng sebaka.

Spiral drill collar ke mofuta oa sesebelisoa sa ho phunya petroleum .Mofuta ona oa ho phunya molaleng o khona ho thibela khatello e fapaneng ea khatello ea lisebelisoa nakong ea ho cheka. Li-spiral grooves li tla etsa hore seretse se phalle ka bolokolohi ho pota-pota molaleng oa boro ho sebelisa khatello ea ho leka-lekana ho thibela ho thehoa ha tšitiso e le ho thibela ka katleho khatello e fapaneng ea khatello. Sebaka sa ho kopana khahlanong le lerako la seliba se ka khaoloa e le ho fokotsa ka katleho monyetla oa ho theha tšitiso ea khatello ea phapang. Li-spiral grooves li tla etsa hore seretse se phalle ka bolokolohi ho pota-pota molaleng oa boro ho sebelisa khatello ea ho leka-lekana ho thibela ho thehoa ha tšitiso e le ho thibela ka katleho khatello e fapaneng ea khatello. Sebaka sa ho kopana khahlanong le lerako la seliba se ka khaoloa e le ho fokotsa ka katleho monyetla oa ho theha tšitiso ea khatello ea phapang. Boima ba molala oa ho phunya spiral ke 4-6% ka tlase ho ea molala oa ho phunya o chitja.

Non-Magnetic Drill Collar: Li-collars tsa Non-magnetic Drill li entsoe ka lisebelisoa tse sa sebetseng tsa makenete tse nang le matla a tlase ka ho kopanya tlhahlobo ea lik'hemik'hale le ts'ebetso ea ho theha hamore ea rotary e nang le matla a tlase a matla a ho kenella ka matla a mochini. re ka fana ka bolelele ho tloha maotong a 10 ho isa ho a 42 le bophara ba kantle ho tloha ho 31/8"ho isa ho 11'.

Tlhaloso ea Sehlahisoa

| Boholo | OD(mm) | ID(mm) | Khoutu | Khoele | Bolelele(mm) | Boima(kg) |

| 3-1/8 | 79.4 | 31.8(1-1/4) | NC23-31 | NC23 | 9140 | 298 |

| 3-1/2 | 88.9 | 38.1(1-1/2) | NC26-35 | NC26 | 9140 | 364 |

| 4-1/8 | 104.8 | 50.8(2) | NC31-41 | NC31 | 9140/9450 | 474/490 |

| 4-3/4 | 120.6 | 50.8(2) | NC35-47 | NC35 | 9140/9450 | 674/697 |

| 5 | 127 | 57.2(2-1/4) | NC38-50 | NC38 | 9140/9450 | 725/749 |

| 6 | 152.4 | 57.2(2-1/4) | NC44-60 | NC44 | 9140/9450 | 1125/1163 |

| 71.4(2-13/16) | NC44-60 | 9140/9450 | 1022/1056 | |||

| 6-1/4 | 158.8 | 57.2(2-1/4) | NC44-62 | NC44 | 9140/9450 | 1237/1279 |

| 71.4(2-13/16) | NC46-62 | 9140/9450 | 1134/1172 | |||

| 6-1/2 | 165.1 | 57.2(2-1/4) | NC46-65 | NC46 | 9140/9450 | 1352/1398 |

| 71.4(2-13/16) | NC46-65 | NC50 | 9140/9450 | 1249/1291 | ||

| 6-3/4 | 171.4 | 57.2(2-1/4) | NC46-67 | NC46 | 9140/9450 | 1471/1521 |

| 7 | 177.8 | 57.2(2-1/4) | NC50-70 | NC50 | 9140/9450 | 1597/1651 |

| 71.4(2-13/16) | NC50-70 | 9140/9450 | 1494/1545 | |||

| 7-1/4 | 184.2 | 71.4(2-13/16) | NC50-72 | NC50 | 9140/9450 | 1625/1680 |

| 7-3/4 | 196.8 | 71.4(2-13/16) | NC56-77 | NC56 | 9140/9450 | 1895/1960 |

| 8 | 203.2 | 71.4(2-13/16) | NC56-80 | NC56/6-5/8REG | 9140/9450 | 2040/2109 |

| 8-1/4 | 209.6 | 71.4(2-13/16) | 6-5/8REG | 6-5/8REG | 9140/9450 | 2188/2263 |

| 9 | 228.6 | 71.4(2-13/16) | NC61-90 | NC61 | 9140/9450 | 2658/2748 |

| 9-1/2 | 241.3 | 76.2(2-13/16) | 7-5/8REG | 7-5/8REG | 9140/9450 | 2954/3054 |

| 9-3/4 | 247.6 | 76.2(3) | NC70-97 | NC70 | 9140/9450 | 3127/3234 |

| 10 | 254 | 76.2(3) | NC70-100 | NC70 | 9140/9450 | 3308/3421 |

| 11 | 279.4 | 76.2(3) | 8-5/8REG | 8-5/8REG | 9140/9450 | 4072/4210 |

Likarolo le Melemo

Mefuta e thata ea 285 ho 341 BHN le boleng ba phello ea Charpy ea 40 ft-lbs e tiiselitsoe bakeng sa lintlha tse 16 tse arolelanoang ka mokhoa o lekanang likarolong leha e le life tsa sefapano mocheso oa kamore;

Likhokahano li koahetsoe ka phosphate ka mor'a ho sebetsa ka mochine ho sireletsa likhoele linthong tse senyang le ho thibela ho ruruha ha ho etsoa ha ho qala;

Metso ea likhoele e bataletse ho likhokahano tsa API;

Litšireletso tsa tšepe tse hatelitsoeng li fanoa bakeng sa melala eohle ea liboro e nang le likhokahano tse tloaelehileng.

Dikgetho

Khatello ea maikutlo groove. Likarolo tsa ho imolla khatello ea maikutlo ho API pin le likhokahano tsa lebokose ho fokotsa khatello e phahameng ea khatello ka hona ho ntlafatsa matla a ho kobeha ho potoloha libaka tsa khokahano.

Ho thetheha ho batang ha metso ea likhoele ho bonts'itse litlamorao tse molemo ho ntlafatsa ho hanyetsa mokhathala oa likhokahano ka ho fokotsa ho qala ha crack.

Hardbanding. Ho tlama ka thata libakeng tse ka tlaase le ka holimo ho phomolo ea ho thella kapa mahetleng a pin ho lelefatsa bophelo ba litšepe tsa ho cheka. E ka boela ea sebelisoa ho litlhophiso tse boletsoeng ke bareki. Ho tlama ka thata libakeng tse ka tlaase le ka holimo ho phomolo ea ho thella kapa mahetleng a pin ho lelefatsa bophelo ba litšepe tsa ho cheka. E ka boela ea sebelisoa ho litlhophiso tse boletsoeng ke bareki.

Libaka tsa ho thella le lifti. Sebaka se kaholimo sa sebaka sa phomolo sa lifti se phuthoa ho ntlafatsa bophelo ba sehlahisoa. Likarolo tsa li-slip le lifti li entsoe ho latela API Spec 7-1.

Room 703 Building B, Greenland center, Hi-tech development zone Xi'an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi'an, China 86-13609153141

86-13609153141