Lihlahisoa

Lisebelisoa tse phahameng tsa Downhole Milling

Boitsebiso ba Sehlahisoa

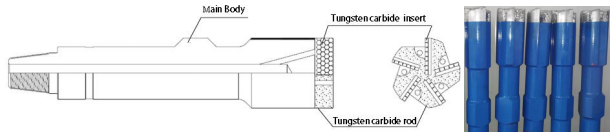

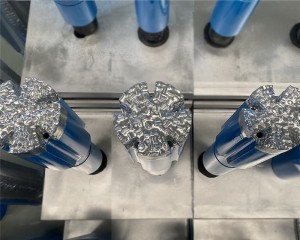

Nka mohlala oa lieta tsa leloala tse bataletseng:

'Mele o ka sehloohong o sebelisa tšepe ea alloy e sebetsang hantle (4145H) ho netefatsa ts'ebetso e boreleli le e sebetsang tlas'a khatello e fapaneng ea ho cheka le boemo ba lebelo la rotary. Ho sa le joalo, re nka metaele ea boemo bo holimo ea tungsten carbide ho fihlela tshilo e potlakileng. Stabilizer le seaparo sa ka ntle bakeng sa leloala le sa sebetseng le leloala la taper li ka etsoa ha ho hlokahala.

Ho kenya tungsten carbide

· Superloy

Filler e ntle bakeng sa mahapu, likhoele le limilo tsa taper.

Molemo ka ho fetisisa bakeng sa tshilo ya junk.

Mefuta e mengata ea boholo bo fumanehang.

Tse matsutlahadi.

· Metal Muncher

Mills kapele ho feta lisebelisoa tse tloaelehileng tsa ho sila.

E fokotsa khatello e hlokahalang ea ho cheka nakong ea ho sila.

E siea maqeba a boreleli a se nang melomo bakeng sa maloanlahla.

E hlahisa maloanlahla a boholo bo tšoanang.

Ho seha tšepe sebakeng sa ho e sila.

· Opti-sehiloeng

Matlakala a manyane.

Ka potlako ROP.

Bophelo bo bolelele.

Khatello e tlase le litlhoko tsa torque.

Lintlha tse 16 tsa ho itšeha le likarolo tse 8 tsa seha se seng le se seng.

Sehlopha sa Lihlahisoa

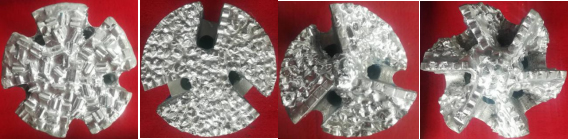

Concave/Flat/Blade Bottom junk mill

E sebelisoa bakeng sa ho sila, khoune, bophara ba meno, phala ea ho hlatsoa, motsoako oa lisebelisoa tsa ho cheka, lisebelisoa tse tebileng tsa pompo ea seliba, sephutheloana, se tsamaisang metsi le lisebelisoa tse ling tse telele tsa ho phunya.

Petrozhr junk mill e fumaneha ka litlhophiso tse fapaneng le lijeometri. Moenjiniere oa rona o tsoetseng pele oa leloala le li-welder tse nang le boiphihlelo li netefatsa sebopeho se tsitsitseng le se tšoarellang sa leloala le leng le le leng la litšila.

Taba. 1 Paramethara ea leloala la Flat/Concave/Blade Bottom junk mill

| Borehole Dia. Mill Shoe OD Bolelele bo khothalelitsoeng (mm) (mm) Screw Thread (mm) | PN E bataletseng | PN Concave | PN E hlasetsoe |

| 95.2- 101.6 89 2-3/8REG 250 | JM089FX | JM089CX | JM089BX |

| 107.9- 114.3 97 2-3/8REG 250 | JM097FX | JM097CX | JM097BX |

| 117.5- 127 110 2-7/8REG 250 | JM110FX | JM110CX | JM110BX |

| 130- 139.7 121 2-7/8REG 250 | JM121FX | JM121CX | JM121BX |

| 142.9- 152.4 130 2-7/8REG 250 | JM130FX | JM130CX | JM130BX |

| 155.6- 165. 1 140 3- 1/2REG 250 | JM140FX | JM140CX | JM140BX |

| 168- 187.3 156 3- 1/2REG 250 | JM156FX | JM156CX | JM156BX |

| 190.5-209.5 178 3- 1/2REG 250 | JM178FX | JM178CX | JM178BX |

| 212.7-241.3 200 4- 1/2REG 250 | JM200FX | JM200CX | JM200BX |

| 244.5-269.9 232 4- 1/2REG 250 | JM232FX | JM232CX | JM232BX |

| 273-295.3 257 6-5/8REG 250 | JM257FX | JM257CX | JM257BX |

| 298.5-317.5 279 6-5/8REG 250 | JM279FX | JM279CX | JM279BX |

| 320.6-346. 1 295 6-5/8REG 250 | JM295FX | JM295CX | JM295BX |

| 349.3-406.4 330 6-5/8REG 250 | JM330FX | JM330CX | JM330BX |

| 406.4-444.5 381 6-5/8REG 250 | JM381FX | JM381CX | JM381BX |

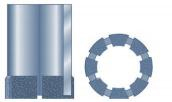

Seeta sa Rotary

Seeta sa Rotary se nka thepa ea carbide ka har'a silinda ho khaola ka holimo ho tlhapi e sa tloaelehang, 'me butle-butle ho lokisa bokaholimo ba tlhapi bo senyehileng ka selikalikoe, joalo ka li-tubing, casing body, joalo-joalo.

[Tlhokomeliso: Hobane bophara ba leino la ka hare la leino la seeta sa rotart bo boholo, torque e ka morao e kholo, kahoo khatello e tlase le mokhoa oa ho potoloha butle o lokela ho amoheloa ts'ebelisong ea seeta sa rotary. Ka kakaretso, khatello ea ho cheka ha ea lokela ho feta 10 KN mme lebelo la ho potoloha ha lea lokela ho feta 50 r/min.]

Mofuta oa A

Seha tšepe, samente le sebopeho.

Ho khaola ho OD le tlase.

Mofuta oa B

Ho seha tshepe moo ho tholahalang ho leng nyane.

Ho khaola ID le tlase.

Mofuta oa C

Khaola sebopeho.

Ho khaola ho OD le tlase.

Mofuta oa D

Khaola sebopeho le litlhapi ka nako e le 'ngoe.

Ho fokotsa ID, OD le tlase.

Tab.2 Rotary shoe parameter

| Casing/ Wellbore Dia. | Rotary shoe OD (mm) | Seeta sa Rotary Bolelele (mm) | Khoele e khothalelitsoeng ea Screw | PN Seeta sa Rotary | |

| 4in | 101.6 limilimithara | 95 400 | FJWP | TXX095 | |

| 5- 1/2in | 139.7 limilimithara | 114 500 | FJWP | TXX114 | |

| 5-3/8in | 146.05mm | 118 500 | FJWP | TXX118 | |

| 6-5/8in | 168.28 limilimithara | 136 425 | FJWP | TXX135 | |

| 7in | 177.8mm | 152 450 | FJWP | TXX152 | |

| 7-5/8in | 193.68 limilimithara | 160 450 | FJWP | TXX160 | |

| 8-5/8in | 219. 1 limilimithara | 185 550 | FJWP | TXX185 | |

| 12- 1/4in 311. 15mm | 203 450 | FJWP | TXX203 | ||

| 15-5/8in 396.88mm | 298 450 | FJWP | TXX298 | ||

| 20in | 508 limilimithara | 406 450 | FJWP | TXX406 | |

Taper Mill

Leloala la taper le hlakola lithibelo, likheo tse oeleng le likarolo tsa liner le lifensetere tsa deburr whipstock le casing. Karolo e tlase ea leloala, ka bophara ba eona e nyane, e kena ka har'a mokotla o oeleng le liner. bophara ba leloala.

Leloala la taper le na le 'mele oa conical le tungsten carbide. 'Mele oa' mele o na le likhato tse 30, khoune e bōpehile ka mapheo, 'me bokaholimo bo thata kapa bo kentse tungsten carbide.

Tab.3 Paramethara ea leloala la Taper

| Borehole Dia. Taper leloala OD E khothalelitsoe Bolelele (mm) (mm)Screw Khoele(mm) | P.N. Taper leloala | ||

| 95- 101.6 | 89 | 2-3/8REG 300 | XZ089 |

| 107.9- 114.3 97 2-3/8REG 300 | XZ097 | ||

| 117.5- 127.0 110 2-7/8REG 300 | XZ110 | ||

| 130- 139.7 121 2-7/8REG 300 | XZ121 | ||

| 142.9- 152.4 130 2-7/8REG 300 | XZ130 | ||

| 155.6- 165. 1 140 3- 1/2REG 300 | XZ140 | ||

| 168- 187.3 156 3- 1/2REG 300 | XZ156 | ||

| 190.5-209.5 178 3- 1/2REG 300 | XZ178 | ||

| 212.7-241.3 200 4- 1/2REG 300 | XZ200 | ||

| 244.5-269.9 232 6-5/8REG 350 | XZ232 | ||

| 273-295.3 257 6-5/8REG 350 | XZ257 | ||

| 298.5-317.5 279 6-5/8REG 350 | XZ279 | ||

| 320.6-346. 1 295 6-5/8REG 350 | XZ295 | ||

| 349.3-406.4 330 6-5/8REG 350 | XZ330 | ||

| 406.4-444.5 381 6-5/8REG 350 | XZ381 | ||

Leloala la Mehala ea Watermelon

Seeta sa thapo ea lehapu ke e 'ngoe ea lisebelisoa tsa ho sila molemong oa ho khelosa ts'ebetso. E sebelisetsoa ho lokisa casing, reaming le ho bula likanale. Hangata e sebelisoa hang ka mor'a ho bula lifensetere. Sebaka sa ho sila (sebaka sa ho sebetsa) sa leloala la mahapu se kopana le lebota la borehole, 'me qetellong ea moeli o mong le o mong o entsoe e le khoune. Ha fensetere e buloa, leloala la mahapu le ka lelefatsa fensetere ho tloha holimo 'me la tlosa sekhahla le li-burrs tse setseng leboteng la liphaephe nakong ea ho khaola qalong.

Tab.4 parameter ea leloala la leloala la lehapu

| Borehole Dia. Screw (mm/in ) Khoele | Sebaka sa Mosebetsi OD (mm/ka hare) | Bolelele ba Sebaka sa Mosebetsi (mm/in) | Total Length (mm/in) | PN |

| 139.7 (5- 1/2) NC 26 112 (4-7/ 16) 600 (23-5/8) | 1130 (44) | XGMX112 | ||

| 139.7 (5- 1/2) NC 26 116 (4-9/ 16) 600 (23-5/8) | 1130 (44) | XGMX116 | ||

| 139.7 (5- 1/2) NC 26 118 (4-5/8) 600 (23-5/8) | 1130 (44) | XGMX118 | ||

| 139.7 (5- 1/2) NC 31 120 (4-3/4) 600 (23-5/8) | 1280 (50) | XGMX120 | ||

| 146.0 (5-3/4) NC 31 124 (4-7/8) 600 (23-5/8) | 1280 (50) | XGMX124 | ||

| 168.3 (6-5/8) NC 31 142 (5-9/ 16) 600 (23-5/8) | 1280 (50) | XGMX142 | ||

| 177.8 (7) NC 31 151 (5- 15/ 16) 600 (23-5/8) | 1280 (50) | XGMX151 | ||

Leloala la lifofane

Pilot mill e etselitsoe ho sila casing, liner, rotary shoe kapa li-tubing tse kholo tsa ID. Li-blades tsa ho itšeha tse apereng ka lisebelisoa tse phahameng tsa tungsten carbide li etsa hore Petrozhr pilot mill e ka finyella ho kenella ka potlako ka ho apara ho fokolang. 'Me pilot end e sebelisetsoa ho tsitsisa ID ea ntho e siloa.

Tab.5 Pilot mill parameter

| Borehole Dia. (mm) | Screw Khoele | Sebaka sa Mosebetsi OD (mm) | Lehare la ho seha Bolelele (mm) | Pilot area Length (mm) | PN |

| 153 2 3/8REG | 130 200 | ≧45 | LYMX130 | ||

| 165 2 3/8REG | 140 200 | ≧45 | LYMX140 | ||

| 187 3 1/2REG | 156 200 | ≧55 | LYMX156 | ||

| 210 4 1/2REG | 178 200 | ≧55 | LYMX178 | ||

| 241 4 1/2REG | 200 200 | ≧55 | LYMX200 | ||

| 270 4 1/2REG | 232 200 | ≧55 | LYMX232 | ||

| 295 6 5/8REG | 257 250 | ≧55 | LYMX257 | ||

| 317 6 5/8REG | 279 250 | ≧55 | LYMX279 | ||

| 346 6 5/8REG | 295 300 | ≧55 | LYMX295 | ||

| 406 6 5/8REG | 330 300 | ≧55 | LYMX330 | ||

| 445 6 5/8REG | 331 300 | ≧55 | LYMX331 | ||

Chate ea kopo ea Tungsten carbide

| Sesebelisoa se khothalelitsoeng | Superloy | Opti-cut | Motsoako oa tšepe | Motsoako oa tšepe le Superloy |

| Hlatsoa lesoba le bulehileng | √ | √ | ||

| Pipe ea ho phunya oashover | √ | |||

| Washover gravel pakete | √ | √ | ||

| Washover liner trim | √ | |||

| Sephutheloana sa Washover | √ | |||

| Ho sila poil | √ | |||

| Ho hlepha ha litšila | √ | √ | ||

| Sephutheloana sa ho ema kapa peipi kapa tubingjunk milling | √ | |||

| Ho sila lehapu | √ | |||

| Ho sila ka likhoele | √ |

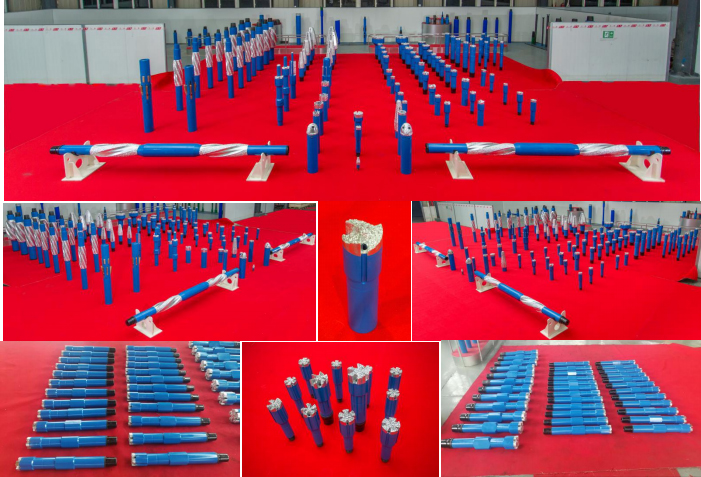

Litšoantšo tsa Ntho ea ho Tšoasa Litlhapi

Room 703 Building B, Greenland center, Hi-tech development zone Xi'an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi'an, China 86-13609153141

86-13609153141