Lihlahisoa

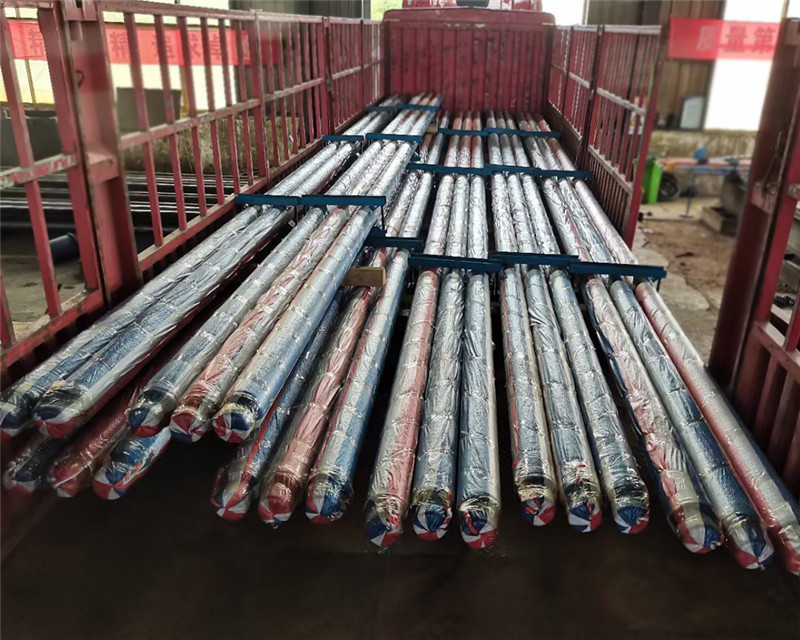

Li-Collars tsa Non-Magnetic Drill & subs

Non-Manetiki ea ho Drill Collar

Slick Non-Mag Drill Collar

Slick Non-Mag Drill Collar e fana ka boima bo hlokahalang holim'a biti, 'me e ke ke ea kena-kenana le bokhoni ba ho cheka ka tsela.

Spiral Non-Mag Drill Collar

Spiral Non-Mag Drill Collar e etselitsoe ho lumella sebaka se seholo sa phallo bakeng sa maro a ho cheka, ha e ntse e fana ka melemo ea tšepe e se nang mag bakeng sa mananeo a rarahaneng a ho cheka.

Flex Non-Mag Drill Collar

Flex Non-Mag Drill Collar e tšesaane ebile e tenyetseha ho feta molala o tloaelehileng oa ho phunya.Bokhoni ba tsona ba ho thinya radius e khuts'oane, ho kobeha bakeng sa li-angles tse phahameng tsa ho haha, le ho feta har'a li-doglegs tse matla li li etsa hore e be tse loketseng bakeng sa ho sebelisoa lits'ebetsong tse tobileng le tse tšekaletseng.E entsoe ka tšepe e se nang mag, molala ona oa ho phunya o loketse hantle lisebelisoa tsa bolulo tsa MWD.

Tlhaloso ea Sehlahisoa

| Lihokelo | OD mm | ID mm | Bolelele mm |

| NC23-31 | 79.4 | 31.8 | 9150 |

| NC26-35 | 88.9 | 38.1 | 9150 |

| NC31-41 | 104.8 | 50.8 | 9150 kapa 9450 |

| NC35-47 | 120.7 | 50.8 | 915 kapa 9450 |

| NC38-50 | 127.0 | 57.2 | 9150 kapa 9450 |

| NC44-60 | 152.4 | 57.2 | 9150 kapa 9450 |

| NC44-60 | 152.4 | 71.4 | 9150 kapa 9450 |

| NC44-62 | 158.8 | 57.2 | 9150 kapa 9450 |

| NC46-62 | 158.8 | 71.4 | 9150 kapa 9450 |

| NC46-65 | 165.1 | 57.2 | 9150 kapa 9450 |

| NC46-65 | 165.1 | 71.4 | 9150 kapa 9450 |

| NC46-67 | 171.4 | 57.2 | 9150 kapa 9450 |

| NC50-67 | 171.4 | 71.4 | 9150 kapa 9450 |

| NC50-70 | 177.8 | 57.2 | 9150 kapa 9450 |

| NC50-70 | 177.8 | 71.4 | 9150 kapa 9450 |

| NC50-72 | 184.2 | 71.4 | 9150 kapa 9450 |

| NC56-77 | 196.8 | 71.4 | 9150 kapa 9450 |

| NC56-80 | 203.2 | 71.4 | 9150 kapa 9450 |

| 6 5/8REG | 209.6 | 71.4 | 9150 kapa 9450 |

| NC61-90 | 228.6 | 71.4 | 9150 kapa 9450 |

| 7 5/8REG | 241.3 | 76.2 | 9150 kapa 9450 |

| NC70-97 | 247.6 | 76.2 | 9150 kapa 9450 |

| NC70-100 | 254.0 | 76.2 | 9150 kapa 9450 |

| 8 5/8REG | 279.4 | 76.2 | 9150 kapa 9450 |

Non Magnetic Stabilizer

Integral non magnetic stabilizer e entsoe ka forging e le 'ngoe e tiileng ea tšepe e se nang makenete.Thepa ke bohloeki bo phahameng ba Chromium Manganese Austenitic tšepe e sa hloekang.

Tlhahlobo ea Ultrasonic le litlhahlobo tsa MPI li etsoa ho forging e 'ngoe le e' ngoe ho feta bolelele ba eona le karolo e feletseng, ka mor'a ho sebetsa ka thata ho latela API Spec 71. Litifikeiti tsa tlhahlobo ea Mill ho kenyeletsa thepa ea mochine, tlhahlobo ea lik'hemik'hale, thepa ea khoheli le litlhahlobo li fanoa ka li-stabilizers tsohle.

Re na le bokhoni ba ho hlahisa Non Magnetic Stabilizer ho fihlela Crown OD 26''

Tlhaloso ea Sehlahisoa

| Matla a tšepe | Kotulo Matla | Ho thatafala | Magnetic Permeability | |

| min. | min. | min. | MAX | Karolelano |

| 120KSI | 100KSI | 285HB | 1.01 | 1005 |

Non Magnetic MWD Sub

Non Magnetic MWD Sub e entsoe ka tšepe e sa hloekang ea Chromium Manganese Austenitic, pipe ea khatello ea khatello ea maikutlo e entsoe ka thepa e seng ea ho kenya li-impulser tsa MWD ka hare le har'a tse ling.Non Magnetic MWD Sub e 'nile ea sebelisoa haholo ke lik'hamphani tsa naha le tsa machaba tsa ho cheka.

Likhokahano tsohle li entsoe ho latela API Spec.7-2 mme metso ea likhoele e sebetsa ka mokhoa o batang ebile e koahetsoe ka komporo ea khoele ea API mme e hlomelloa ka basireletsi.

Tlhaloso ea Sehlahisoa

| Diameter (mm) | Ka hare bophara (mm) | Ka hare bore bolelele (mm) | Boemo bo tlase lesoba (mm) | Kakaretso ea maoto (mm) |

| 121 | 88.2 | 1590 | 65 | 2500 |

| 172 | 111.5 | 1316 | 83 | 2073 |

| 175 | 127.4 | 1280 | 76 | 1690 |

| 203 | 127 | 1406 | 83 | 2048 |

LANDRILL Non Magnetic Materials standard

Lintho tseo e seng tsa Magnetic:

Relative Permeability: Max 1.005

Sebaka se chesang / Sekhahla sa Tšimo: MAX ±0.05μT

Kalafo e Khethehileng ho ID: Roller Burnishing

Ka mor'a ho chesoa ha li-roller, lesela le hatellang lea hlaha, melemo e latelang:

Eketsa thepa ea ho hanyetsa kutu, Eketsa ho thatafala ha bokaholimo ho fihla ho HB400, Eketsa bokaholimo ba bore ho Ra≤3.2 μm, Teko le Tlhahlobo e etsoang bareng ka 'ngoe nakong ea tlhahiso ea likarolo tsa NMDC, Stabilizer le MWD.

Sebopeho sa Lik'hemik'hale, Teko ea Teko, Teko ea Tšusumetso, Teko ea Bothata, Teko ea Metallographic (Boholo ba lijo-thollo), Teko ea Corrosion (Ho ea ka ASTM A 262 Practice E), Tlhahlobo ea Ultrasonic ka bolelele bohle ba bar (Ho ea ka ASTM A 388), Relative magazine. Teko ea permeability, Teko ea Sebaka se chesang, Tlhahlobo ea Dimensional, joalo-joalo.

Mekhoa e khethehileng ea phekolo ea holim'a metsi: Ho penta ha hamore, ho chesoa ha rolara, ho phunya.

Room 703 Building B, Greenland center, Hi-tech development zone Xi'an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi'an, China 86-13609153141

86-13609153141